Using upstream anaerobic digestion process-control to achieve minimal content of undesired trace elements

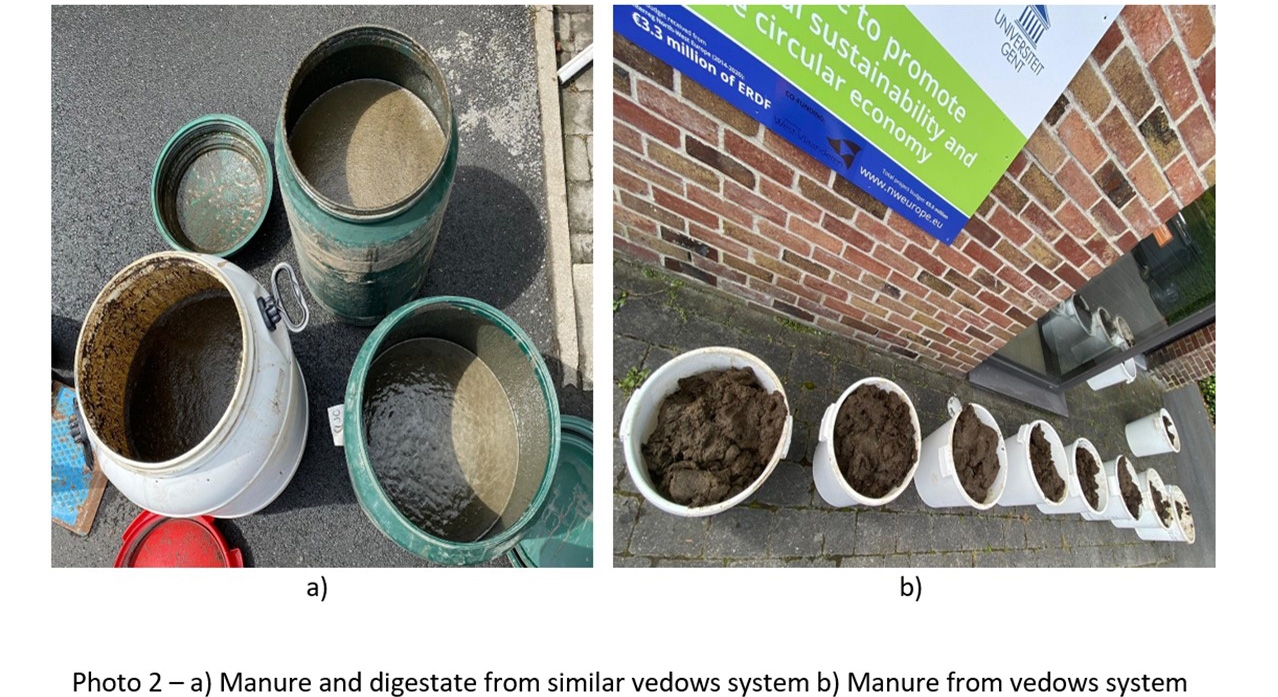

In the initial part of my research project, entitled “Using upstream anaerobic digestion process-control to achieve minimal content of undesired trace elements”, I conducted a mono-digestion of pig manure during my secondment at Innolab, a corporate spin-off from Ghent University, located in Oostkamp (Belgium). For starting the reactors (Photo 1a), pig manure and digestate (inoculum) (Photo 2a) were used to start semi-continuous reactors (32 L), which were fed every day with manure from vedows system (Photo 2b). Such a system consists of a shallow cellar underneath a slatted floor, enabling the primary separation of solid manure and urine. By using the solid fraction of manure as a feedstock for biogas production, a higher up-concentration of heavy metals (HMs) in the digestate is expected. Some parameters such as biogas production (Nm3 t-1), CH4 (%), CO2 (%), O2 (%), CO (ppm) and H2S (ppm) were registered during 45 days. Digestate samples were also collected every 15 days to analyze nutrient content and HMs concentration, and bioavailability during the process. Currently, metals analysis have been conducted in the Laboratory of Analytical Chemistry and Applied Ecochemistry (Ecochem) from Ghent University. The main goal is to measure the HM bioavailability via the BCR analysis, in which four metal concentration fractions are analyzed (Soluble and exchangeable metals - F1; carbonates, oxides and reducible metals - F2; metals bound to organic matter; oxidizable and sulphidic metals - F3; and residual metals - F4). The bioavailability of HMs will be further analyzed in the following downstream process, an hydrothermal treatment of the digestate to create hydrochar, whose product is expected to have less HMs bioavailability. The next step will be to compare the results with digestate produce from the-co-digestion of pig manure from vedows system and maize grown on a highly contaminated soil.

In the initial part of my research project, entitled “Using upstream anaerobic digestion process-control to achieve minimal content of undesired trace elements”, I conducted a mono-digestion of pig manure during my secondment at Innolab, a corporate spin-off from Ghent University, located in Oostkamp (Belgium). For starting the reactors (Photo 1a), pig manure and digestate (inoculum) (Photo 2a) were used to start semi-continuous reactors (32 L), which were fed every day with manure from vedows system (Photo 2b). Such a system consists of a shallow cellar underneath a slatted floor, enabling the primary separation of solid manure and urine. By using the solid fraction of manure as a feedstock for biogas production, a higher up-concentration of heavy metals (HMs) in the digestate is expected. Some parameters such as biogas production (Nm3 t-1), CH4 (%), CO2 (%), O2 (%), CO (ppm) and H2S (ppm) were registered during 45 days. Digestate samples were also collected every 15 days to analyze nutrient content and HMs concentration, and bioavailability during the process. Currently, metals analysis have been conducted in the Laboratory of Analytical Chemistry and Applied Ecochemistry (Ecochem) from Ghent University. The main goal is to measure the HM bioavailability via the BCR analysis, in which four metal concentration fractions are analyzed (Soluble and exchangeable metals - F1; carbonates, oxides and reducible metals - F2; metals bound to organic matter; oxidizable and sulphidic metals - F3; and residual metals - F4). The bioavailability of HMs will be further analyzed in the following downstream process, an hydrothermal treatment of the digestate to create hydrochar, whose product is expected to have less HMs bioavailability. The next step will be to compare the results with digestate produce from the-co-digestion of pig manure from vedows system and maize grown on a highly contaminated soil.